Die casting production and processing

Key words:

Classification:

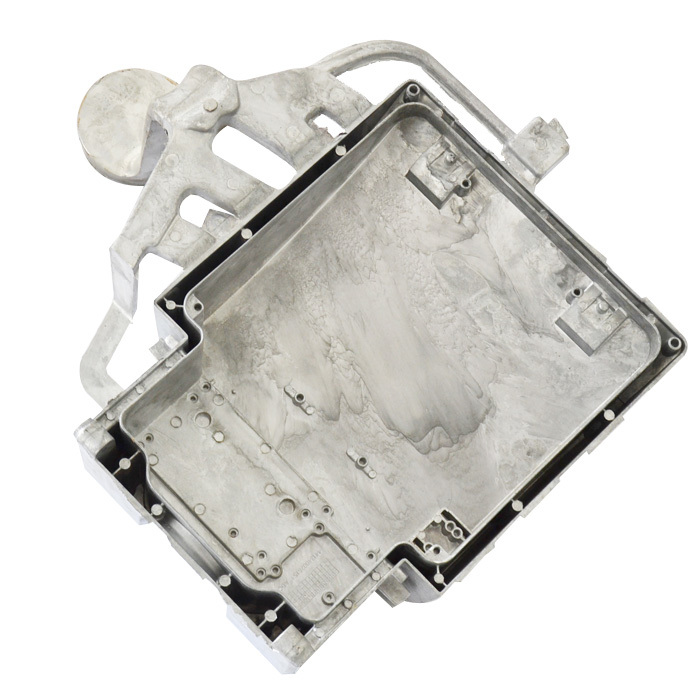

Description

Twenty years of experience in die casting, to provide you with precision die casting products.

Huizhou Shuangcheng Hardware Die Casting Products Co., Ltd. was founded in 2007, with a plant area of 6000 square meters and 150 employees. Is a professional for lighting, sanitary ware, electrical appliances, furniture, electronic products, shell and all kinds of LED cooling equipment, providing precision components die casting enterprises.

The company's products are hardware die casting, die casting structural parts, die casting mold, zinc alloy die casting, die casting parts, aluminum alloy die casting and other die casting products, is a professional metal die casting, die casting structural parts, zinc alloy die casting, die casting parts, aluminum alloy die casting, die casting mold factory, From mold design, mold manufacturing, die casting production, precision machining, surface sandblasting, paint baking, powder spraying, electroplating treatment and other integrated services.

ADC12 die casting is a premium quality aluminum alloy known for its excellent mechanical properties, corrosion resistance, and castability, making it the preferred choice for a wide range of industrial applications. This alloy is widely used in the production of precision die-cast components, particularly in the automotive, electronics, and consumer goods sectors. ADC12 die casting provides superior strength-to-weight ratios, making it ideal for lightweight, high-performance parts that require both durability and reliability.

One of the key advantages of ADC12 die casting is its ability to produce intricate and complex shapes with high dimensional accuracy. This is achieved through the die-casting process, where molten ADC12 aluminum alloy is injected into molds under high pressure, resulting in smooth, consistent surfaces and tight tolerances. The excellent fluidity of ADC12 ensures that even the most detailed and thin-walled components can be produced with minimal defects, making it an ideal solution for producing high-quality parts.

In addition to its superior castability, ADC12 die casting also offers outstanding corrosion resistance, which is particularly valuable in automotive and outdoor applications. The alloy forms a protective oxide layer on its surface, preventing the onset of corrosion and ensuring a long service life in harsh environments. This corrosion resistance, combined with its low density and excellent thermal conductivity, makes ADC12 die casting components an essential part of modern engineering solutions, where both performance and longevity are paramount.

ADC12 die casting is not only ideal for manufacturing automotive parts like engine components, transmission housings, and brackets, but it is also widely used in electronics for the production of housings for devices like computers, smartphones, and other consumer electronics. The combination of high mechanical properties, lightweight nature, and exceptional durability makes ADC12 die casting a versatile and cost-effective solution for a wide range of industries.

Product display

Product display

Product display

Product display

Product display

Product display

Product display

Product display

Related Products

Quotation Of Product