Huizhou Hardware Die Casting Factory

Key words:

Classification:

Description

Twenty years of experience in die casting, to provide you with precision die casting products.

Huizhou Shuangcheng Hardware Die Casting Products Co., Ltd. was founded in 2007, with a plant area of 6000 square meters and 150 employees. Is a professional for lighting, sanitary ware, electrical appliances, furniture, electronic products, shell and all kinds of LED cooling equipment, providing precision components die casting enterprises.

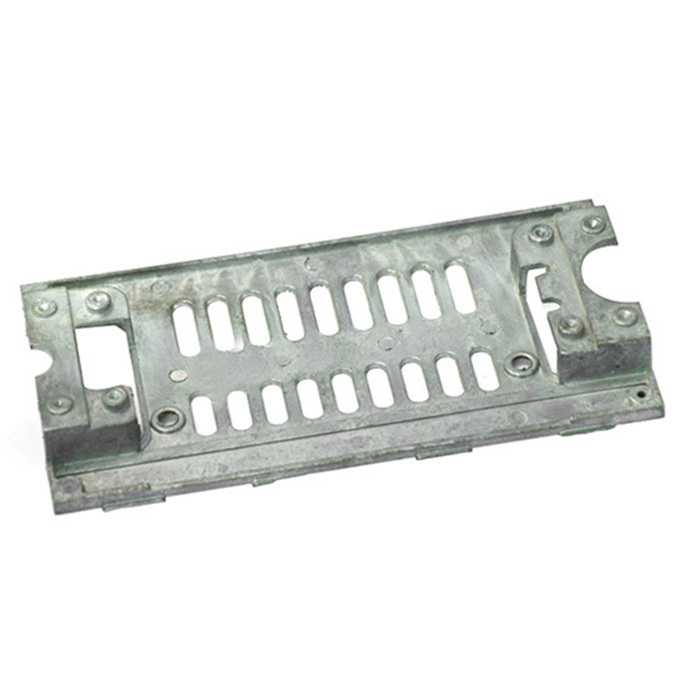

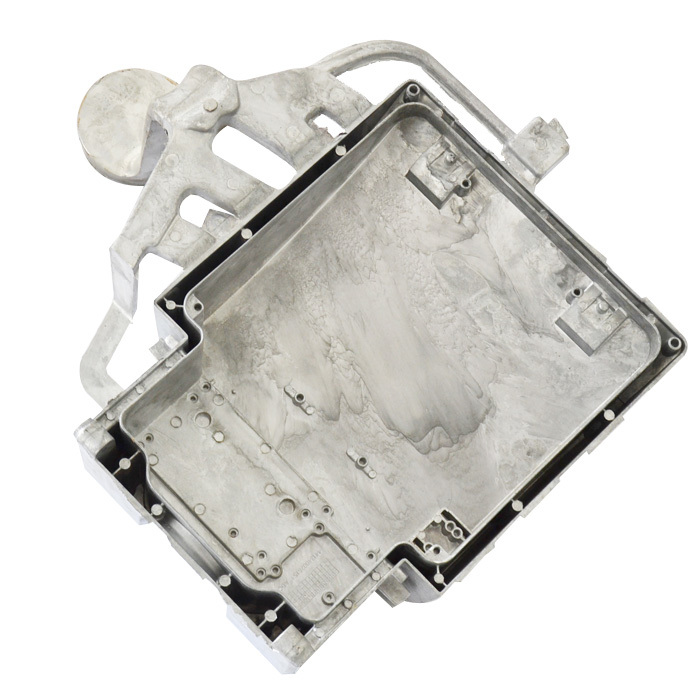

The company's products are hardware die casting, die casting structural parts, die casting mold, zinc alloy die casting, die casting parts, aluminum alloy die casting and other die casting products, is a professional metal die casting, die casting structural parts, zinc alloy die casting, die casting parts, aluminum alloy die casting, die casting mold factory, From mold design, mold manufacturing, die casting production, precision machining, surface sandblasting, paint baking, powder spraying, electroplating treatment and other integrated services.

Our expertise lies in the advanced manufacturing process of A380 aluminum die casting, which allows us to produce high-volume, complex components with exceptional precision. As one of the most widely used aluminum alloys for die casting, A380 offers an outstanding combination of strength, fluidity, and thermal properties. This makes it the ideal choice for creating thin-walled, lightweight parts without sacrificing structural integrity, meeting the rigorous demands of industries such as automotive and consumer electronics.

The inherent advantages of the A380 aluminum die casting process are rooted in the material's excellent characteristics. The alloy's superior fluidity enables it to fill intricate mold details effortlessly, resulting in components with excellent surface finishes and dimensional accuracy. Furthermore, its high strength-to-weight ratio and good corrosion resistance ensure that the final products are both durable and lightweight, a critical requirement for applications where performance and efficiency are paramount.

We leverage state-of-the-art machinery and precision tooling to fully exploit the potential of A380 aluminum die casting. Our highly automated systems ensure consistent quality and repeatability across large production runs, significantly reducing per-part costs. The efficiency of this process also minimizes secondary machining operations, leading to faster production cycles and quicker time-to-market for our clients, giving them a significant competitive advantage.

Choosing our services for your A380 aluminum die casting needs guarantees a reliable and cost-effective manufacturing solution. We are committed to delivering components that consistently meet the highest standards of quality and performance. From prototyping to full-scale production, our technical support team works closely with you to optimize part design for the die casting process, ensuring superior results and total project success.

Product display

Product display

Product display

Product display

Product display

Product display

Product display

Product display

Related Products

Quotation Of Product